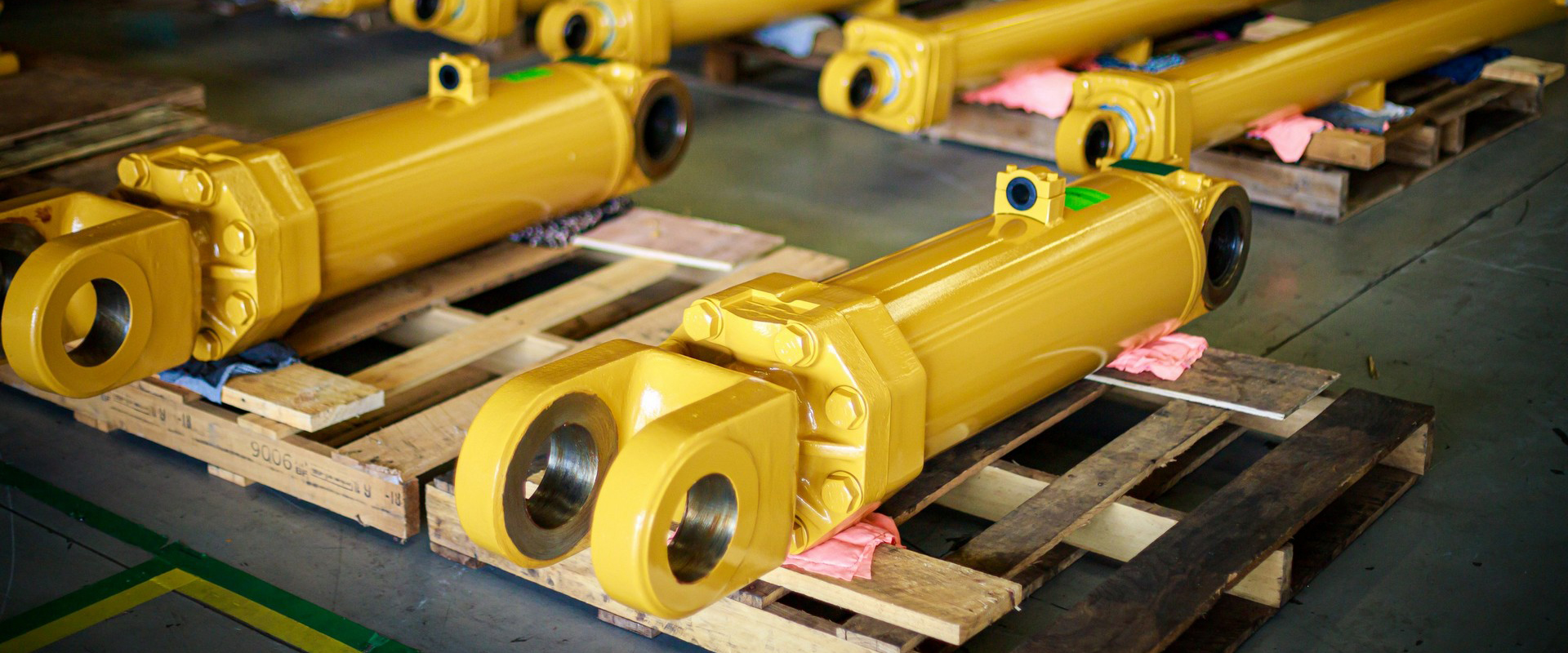

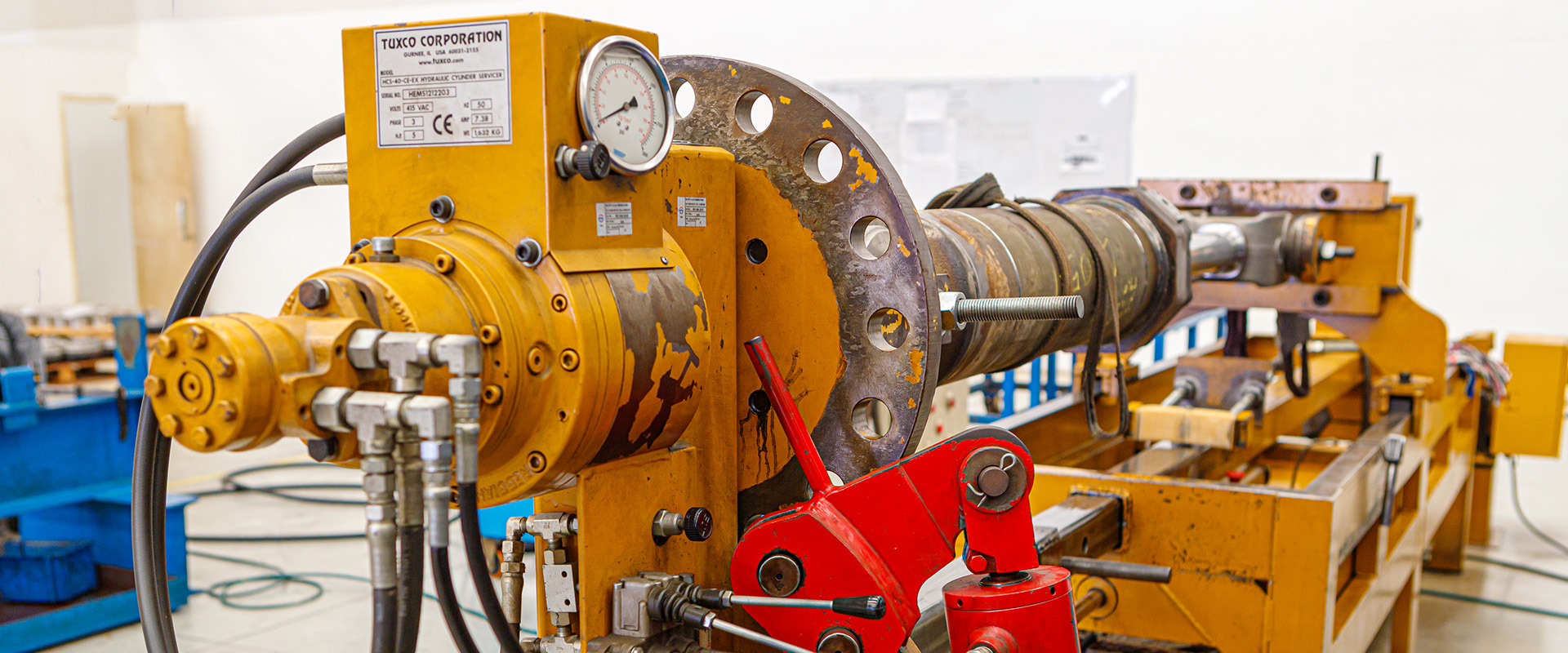

Delta's competitive advantage in the global hydraulic market is its sophisticated in-house design, engineering and end-to-end manufacturing capability that enables the company to provide rapid and flexible design, engineering and manufacture and deliver precision quality product to our customers, that meets their requirements, whether it is a one-off project or high production volume OEM product.

Delta has 2D and 3D CAD designing and drafting with Finite Element Analysis (FEA) stress testing capability.

Our 8,300m2 manufacturing facility in Devonport and 9,000m2 facility in Thailand have extensive machining capabilities with an impressive range of CNC Lathes, CNC Turning Centres, CNC Machining Centres, Manual Lathes and Manual Mills. Our CNC Turning capacity utilises ten machines machining from 1000mm diameter x 3 metres down, with hollow spindle capacity to 520mm. Machine centres utilising six machines incorporating 4 axis horizontal, 4 axis vertical to 700 x 1200 x 600, and 3 axis vertical machines.

Our grinding capacity is second to none with centre grinding to 1000 diameter x 7000 long, 3 centreless machines providing from 25-300 dia x 12000 long plus internal grinding to 500 ID x 400 long and surface grinding.

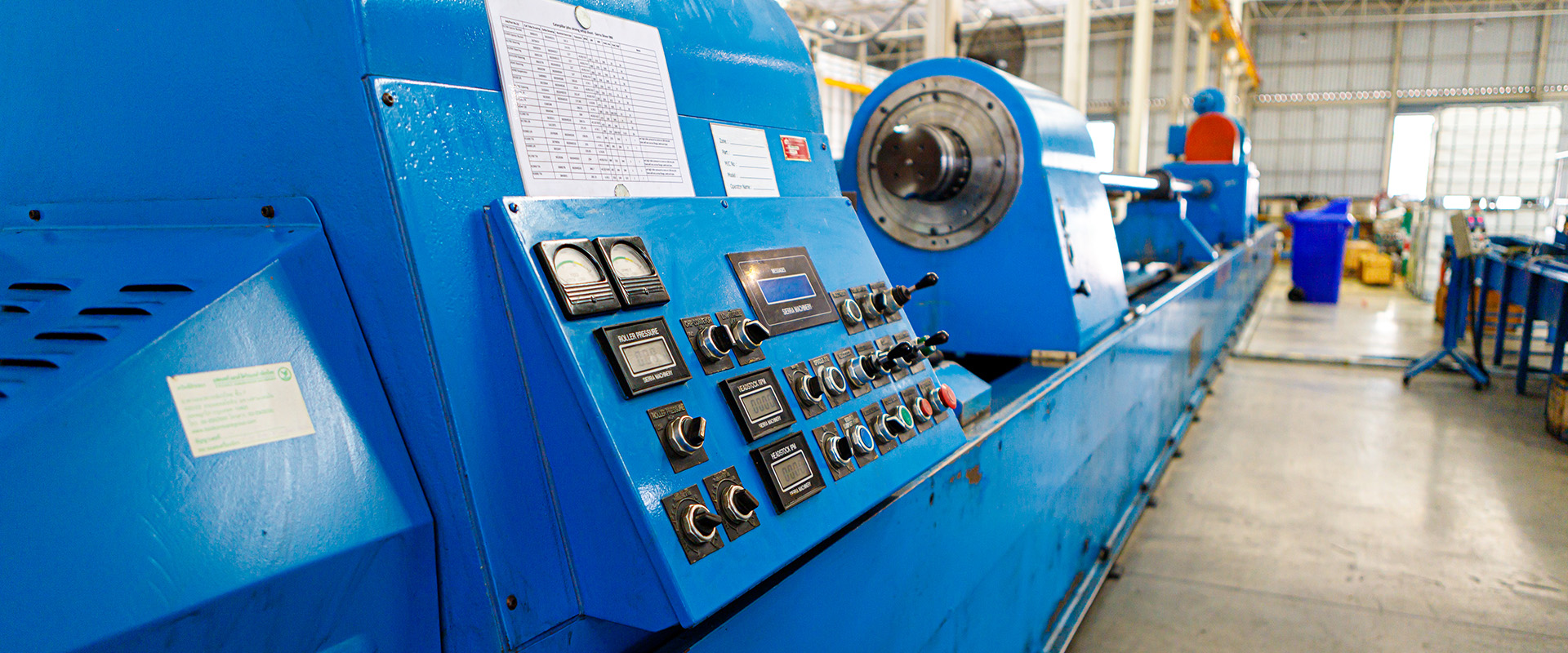

Internal cylinder surface finishing is achieved via a state of the art skiving-burnishing machines.

Delta has two friction welding machines, a 160 tonne machine, and a 650 tonne machine which is the largest friction welder in the southern hemisphere, as well as induction hardening machines.

Delta utilises the world's first horizontal reciprocating in-solution chrome plating machine which can chrome cylinders 12 metres in length and our vertical hard chrome facility is the largest in Australia. The 9 metre deep vertical tanks and solid state computer controlled rectifiers can handle work pieces up to 8.5 metres long and provide in process triplex plating.

Delta has a Department of Defence certified 120 square metre clean room facility which is used for the production of manifolds and the assembly of smaller cylinders for defence and medical applications.

It is also used as a hydraulic engineering training facility for college students.

Devonport is on the northern coast of Tasmania and sits in the centre of major sea and air freight infrastructure.

Delta Thailand is next to Caterpillar Underground Mining and opposite Caterpillar Tractor and Earthmoving in Rayong.

Delta has a 99% customer delivery KPI and absorbs additional freight costs to achieve ontime delivery if necessary.